Manufacturing Process

With dedicated full-time staff providing in-house cutting, welding, bending, rigging, assembly, and paint expertise, Metal Shark maintains tight control over all aspects of production to assure the highest consistency and quality.

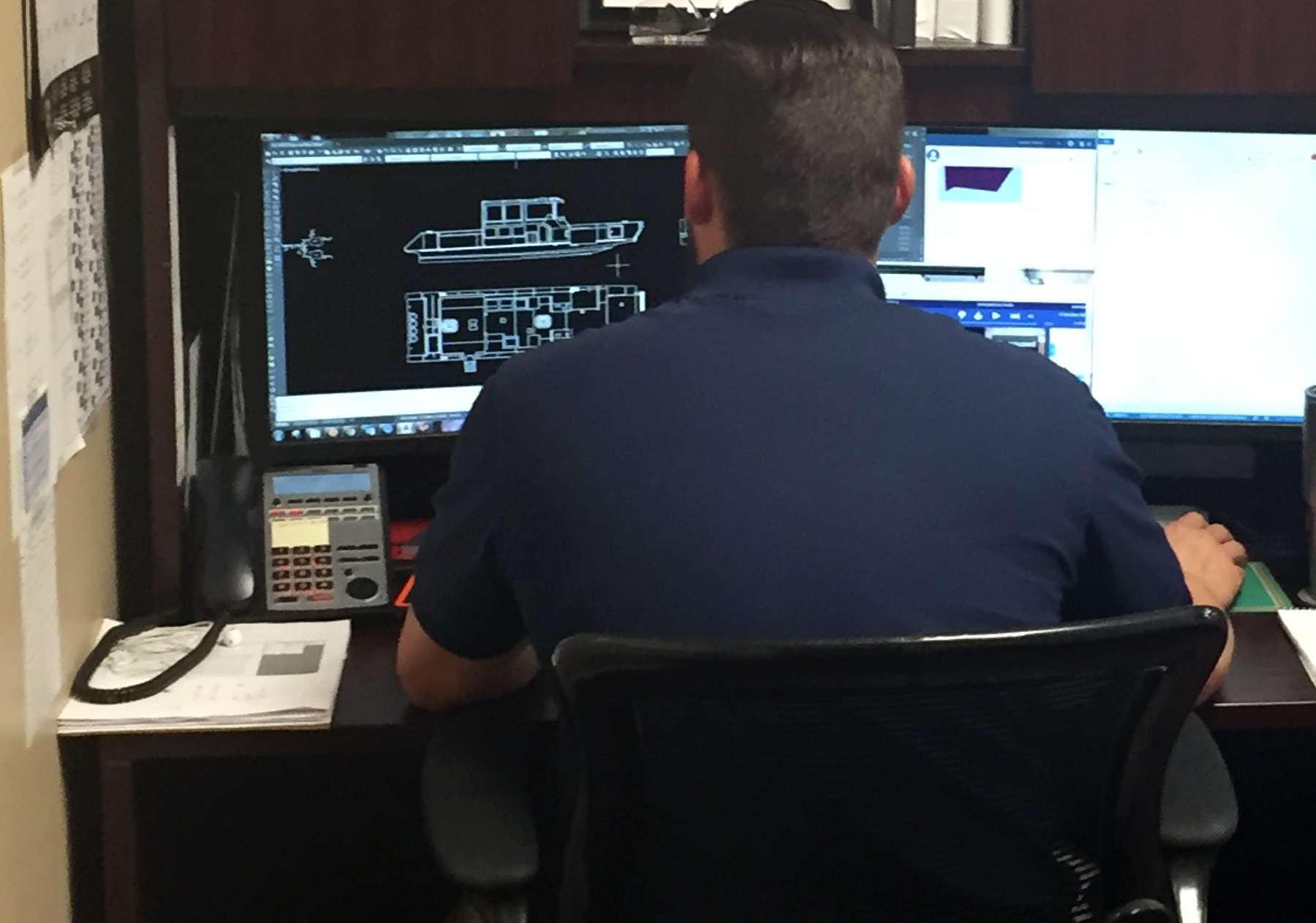

The manufacturing process begins in Metal Shark’s engineering office. A staff of over 60 in-house naval architects, marine and mechanical engineers use leading engineering and 3D parametric modeling software applications to precisely model every piece of each vessel from bow to stern. The resulting data is then fed to computer-driven cutting and bending machinery that fabricates each piece from sheets of premium 5086 aluminum alloy. Then manufacturing progresses to Metal Shark’s highly skilled welding and assembly teams.

Metal Shark designs and constructs all vessels to industry standard guidelines and in full compliance with USCG, ASTM, ABS, ABYC, AWS and all other relevant governing bodies.

Click to learn more about our Franklin Shipyard and Jeanerette Production Facility.